High Quality DF Defoamer White, easily ?owing powder

Product overview

Defoamer (Defoamer) is a chemical additive capable of eliminating or inhibiting foam production in liquids.

product characteristics

Rapid defoaming ability: can quickly destroy the stability of the foam, so that the foam quickly burst.

Long-lasting foam suppression effect: After the foam is eliminated, the generation of new foam can be prevented for a long time.

Good compatibility: It has good compatibility with the defoaming system and does not affect the basic performance of the system.

High stability: Stable defoaming performance under different temperature, pH and pressure conditions.

Low toxicity, environmental protection: less harm to the human body and the environment.

product use

Industrial production

Paper industry: Eliminate the foam in the pulp, improve the quality of paper.

Coatings and paints: Prevent foam formation during mixing and construction.

Textile printing and dyeing: Solve the foam problem in the dyeing and finishing process.

Petrochemical: In refining, chemical production to eliminate foam, to ensure the smooth progress of production.

Food processing

Fermentation process: Control the foam in the fermentation liquid to improve production efficiency.

Food processing: such as soybean products, beverages and other production of defoaming.

Water treatment

Sewage treatment: prevent the generation of foam, improve the treatment effect.

Production process

There are many kinds of defoamer and different production processes. Common polyether type defoamer is prepared by polymerization reaction, and silicone defoamer is made by emulsification of silicone oil.

Market prospects

With the expansion of production scale in various industries and the improvement of product quality requirements, the market demand for defoamer is increasing. At the same time, the development and application of environmentally friendly and efficient defoamer has also become the development trend of the market.

use precautions

Choose the right type of defoamer: Choose according to the specific application system and the cause of foam.

Control the amount of addition: too little addition may not achieve the antifoam effect, too much may affect the performance of the system.

The correct adding method: Generally can be added directly or after dilution, to ensure uniform dispersion.

For example, in the production of paint, selecting the appropriate defoamer and adding it at the appropriate stage can effectively eliminate bubbles and make the surface of the paint smooth and flat; In sewage treatment, appropriate addition of defoamer can improve the treatment efficiency and reduce the impact of foam on the environment.

In short, Defoamer plays an important role in many industrial production and processing processes, providing a strong guarantee for improving production efficiency and product quality.

Technical indicators

| Model | DF-6050 | |

|---|---|---|

| Appearance | White, easily ?owing powder | |

| PH(20%) | 5.0-9.0 | |

| Bulk density /g/L | 200-400 | |

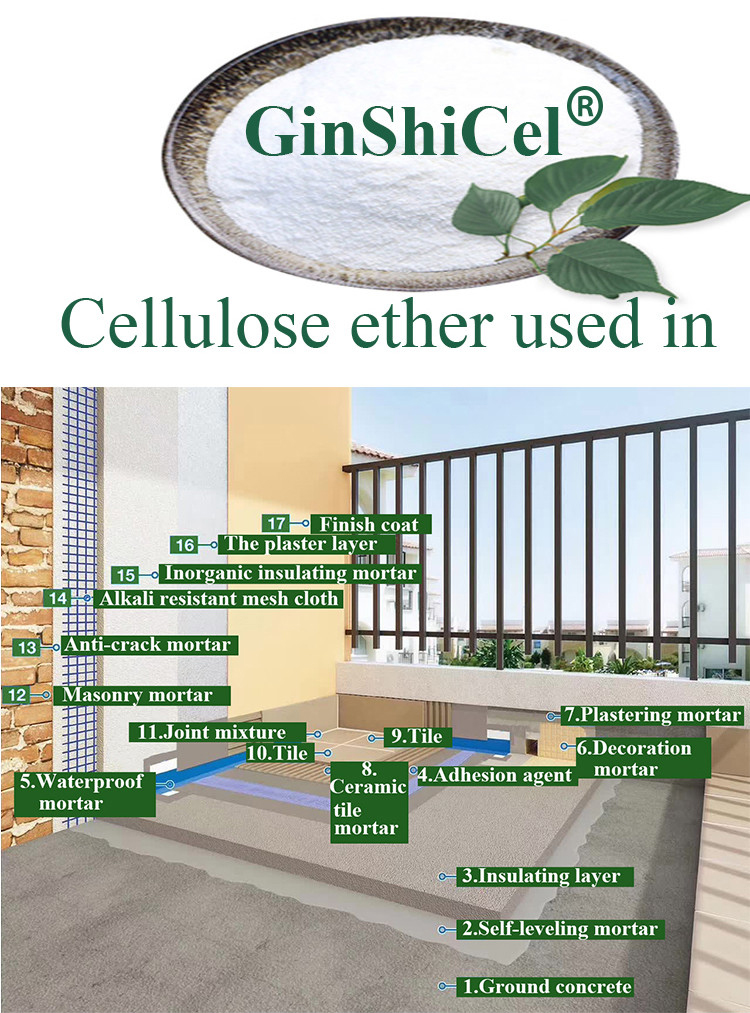

Application areas

? Repair mortar

? Grouting material??

? GRC

? Ground stone ?ooring

Application performance

? Fast defoaming speed and good stability??

? Foam suppression

? Adaptability to various materials

? High temperature resistance performance

? Increases strength of concrete and other materials

details pictures