High Quality HPS Starch Ether

Product overview

Starch ether is a class of products obtained by chemically modifying ether groups into starch molecules, and is usually a white or white-like powder.

product characteristics

Thickening: can significantly increase the viscosity of the system, improve the flow performance.

Water retention: effectively retain water and reduce water loss.

Anti-slip: It can prevent the slip of the material in the building material.

Good compatibility: Good compatibility with various building materials and additives.

product use

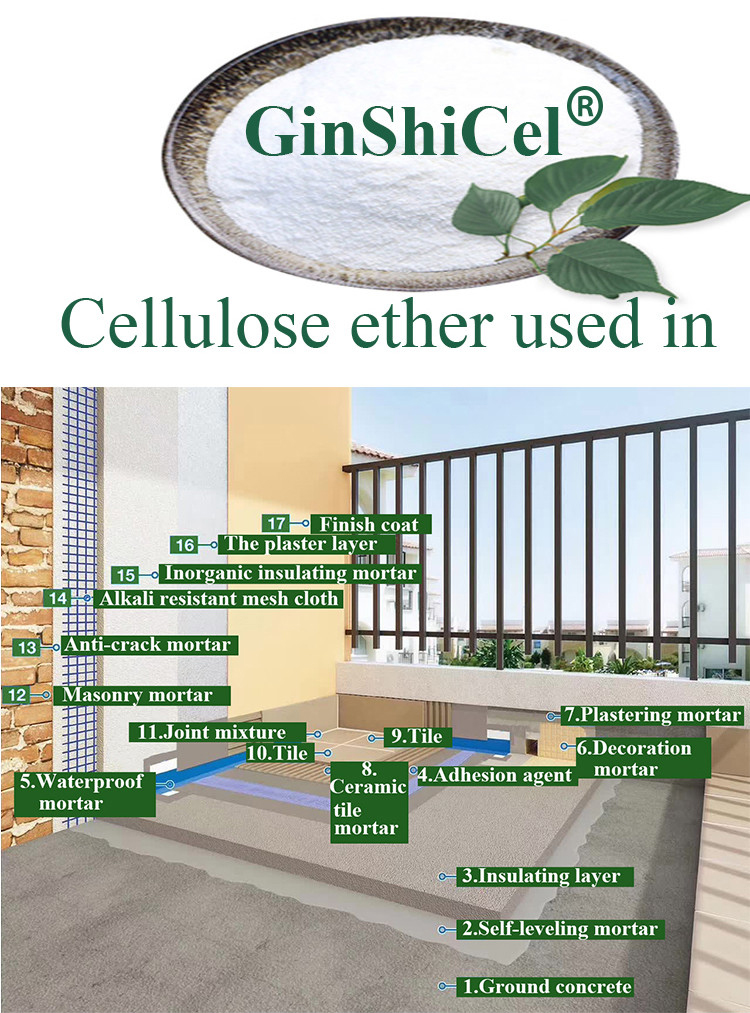

Architectural field

All kinds of dry mix mortar: such as tile glue, plastering mortar, thermal insulation mortar, etc., improve the construction performance and product quality.

Putty: Enhances the batch scraping and crack resistance of putty.

Ceramic industry: Used for ceramic paste to improve its fluidity and stability.

Coating industry: Increase the viscosity and stability of coatings, prevent flow hanging.

Production process

It is generally prepared by the reaction of starch and etherifying agent under specific conditions.

Market prospects

With the increasing demand for high-performance materials in the construction industry, as well as the improvement of environmental protection and energy saving requirements, the application of starch ether in building materials is more and more extensive, and the market prospect is very broad.

use precautions

Storage should be kept dry and ventilated to avoid moisture agglomeration.

When using, the addition amount should be reasonably controlled according to the specific application scenario and formula requirements.

Different types of starch ethers may have differences in performance and should be selected according to actual needs.

For example, in the application of ceramic tile glue, the appropriate addition of starch ether can improve the initial viscosity and anti-slip property of ceramic tile glue to ensure that the ceramic tile is firmly pasted; In putty, it can improve the constructability and crack resistance of putty.

In short, starch ether, as an excellent additive, plays an important role in many industries and provides an effective solution for improving product quality and performance.

Technical indicators

| Model | HPS-301 |

|---|---|

| Appearance | White or light yellow ?owing powder |

| Fineness (80 mesh pass rate) | ≥98 |

| Bulk density /g/L | ≥500 |

| Moisture content /% | ≤12.0 |

| PH(20%) | 5-11 |

| Hydroxypropyl content /% | 14-24 |

Application areas

? Cement-based and gypsum-based

? Mortars?

? Food

? Cosmetics?

? Textiles

? Paint?

? Ink

? Paper?

? Wood

? Other related applications

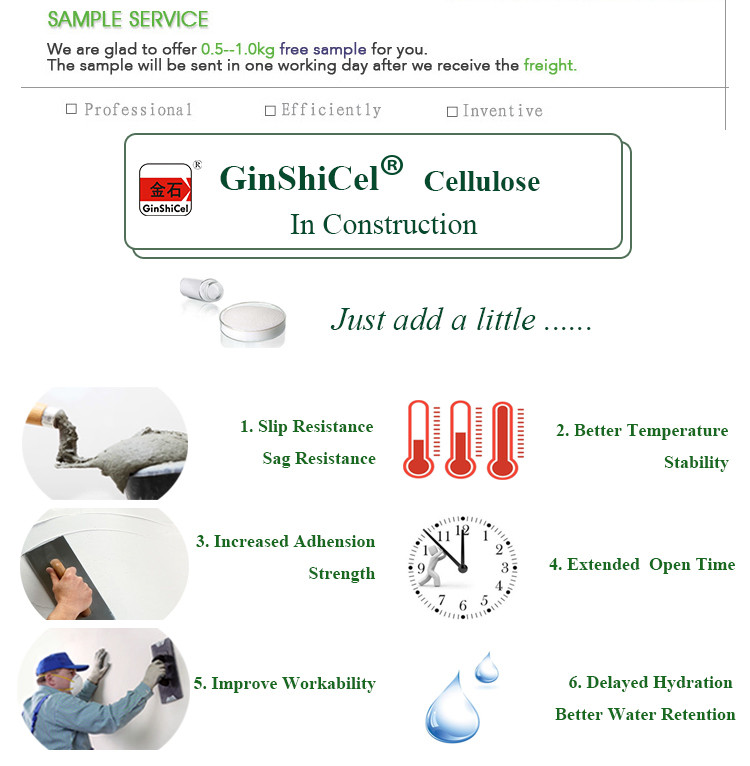

Application performance

? Anti-sagging

? Increases lubricity and ensures smoother application??

? Rapid Thickening

? Prevents layering and segregation of mortar; increases bond strength of mortar?

? Prolongs opening time of mortar

details pictures