High Quality HPS Starch Ether

Cov khoom muag

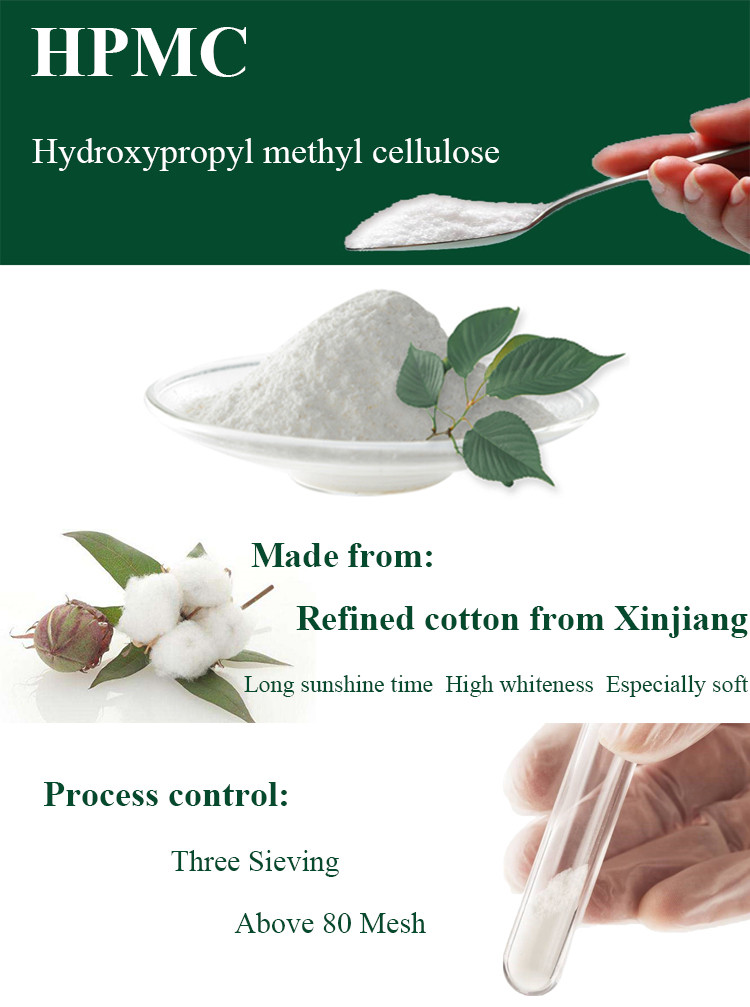

Starch ether yog ib chav kawm ntawm cov khoom tau los ntawm kev hloov kho ether pawg rau hauv cov hmoov txhuv nplej siab, thiab feem ntau yog cov hmoov dawb lossis dawb zoo li hmoov.

cov yam ntxwv ntawm cov khoom

Thickening: tuaj yeem ua kom cov viscosity ntawm lub cev, txhim kho kev ua haujlwm txaus.

Kev tuav dej: khaws cov dej zoo thiab txo cov dej poob.

Anti-slip: Nws tuaj yeem tiv thaiv kev plam ntawm cov khoom hauv cov khoom siv hauv tsev.

Zoo compatibility: Zoo compatibility nrog ntau yam khoom siv tsev thiab additives.

khoom siv

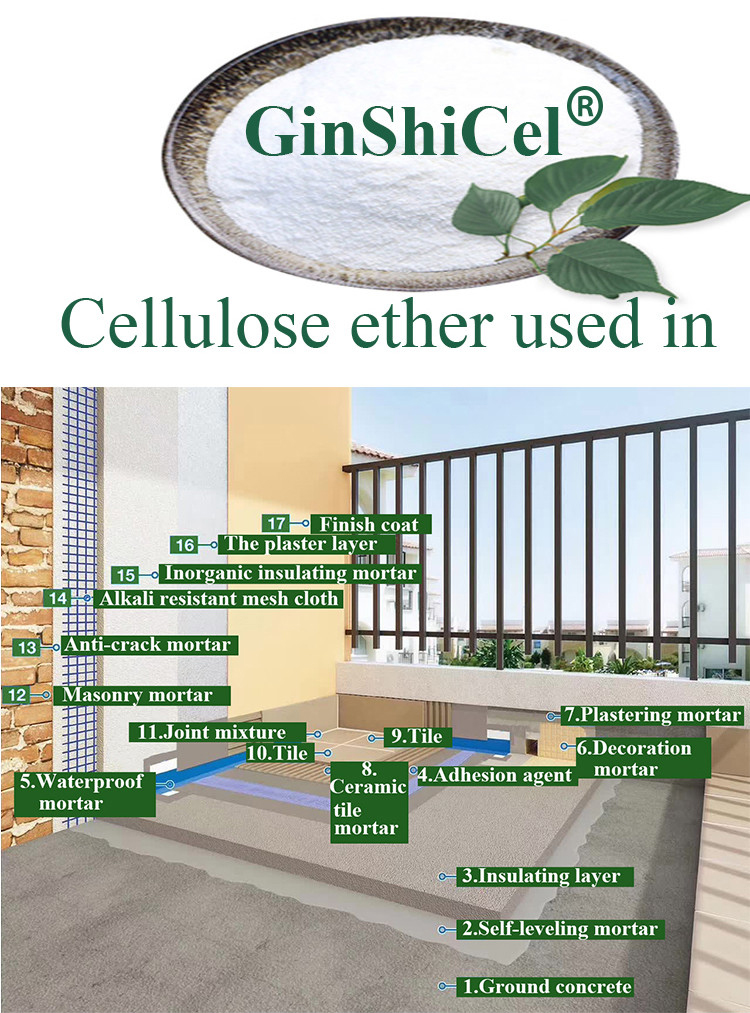

Architectural teb

Txhua yam kev sib xyaw qhuav mortar: xws li pobzeb kua nplaum, plastering mortar, thermal rwb thaiv tsev mortar, thiab lwm yam, txhim kho kev tsim kho thiab cov khoom zoo.

Putty: Txhim kho cov batch scraping thiab tawg tsis kam ntawm putty.

Ceramic kev lag luam: Siv rau ceramic paste los txhim kho nws cov fluidity thiab stability.

Txheej kev lag luam: Ua kom cov viscosity thiab ruaj khov ntawm cov txheej txheem, tiv thaiv kev khiav dai.

Cov txheej txheem ntau lawm

Nws yog feem ntau npaj los ntawm cov tshuaj tiv thaiv ntawm starch thiab etherifying tus neeg sawv cev nyob rau hauv tej yam kev mob.

Kev lag luam zeem muag

Nrog rau kev thov ntau ntxiv rau cov ntaub ntawv ua tau zoo hauv kev tsim kho kev lag luam, nrog rau kev txhim kho kev tiv thaiv ib puag ncig thiab kev txuag hluav taws xob, kev siv cov hmoov txhuv nplej siab ether hauv cov khoom siv hauv tsev yog ntau thiab ntau dua, thiab kev lag luam kev cia siab yog dav heev.

siv ceev faj

Kev khaws cia yuav tsum tau khaws cia kom qhuav thiab tso cua kom tsis txhob ya raws agglomeration.

Thaum siv, qhov sib ntxiv yuav tsum tau tswj kom tsim nyog raws li qhov tshwj xeeb daim ntawv thov scenario thiab cov qauv yuav tsum tau ua.

Ntau hom hmoov txhuv nplej siab ethers yuav muaj qhov sib txawv ntawm kev ua tau zoo thiab yuav tsum tau xaiv raws li qhov xav tau tiag tiag.

Piv txwv li, nyob rau hauv daim ntawv thov ntawm cov pobzeb ceramic kua nplaum, qhov tsim nyog ntxiv ntawm cov hmoov txhuv nplej siab ether tuaj yeem txhim kho qhov pib viscosity thiab cov cuab yeej los tiv thaiv ntawm cov nplais pobzeb kua nplaum kom ntseeg tau tias cov pobzeb ceramic yog ruaj khov; Hauv putty, nws tuaj yeem txhim kho kev tsim kho thiab tawg tsis kam ntawm putty.

Nyob rau hauv luv luv, hmoov txhuv nplej siab ether, raws li ib tug zoo additive, plays lub luag hauj lwm tseem ceeb nyob rau hauv ntau industries thiab muab ib tug zoo tshuaj rau kev txhim kho cov khoom zoo thiab kev ua tau zoo.

Technical ntsuas

| Qauv | HPS-301 |

|---|---|

| Qhov tshwm sim | Dawb los yog lub teeb daj ntws hmoov |

| Fineness (80 mesh pass tus nqi) | ≥98 |

| Ntau qhov ceev /g / L | ≥500 |

| Cov dej noo /% | ≤ 12.0 |

| PH (20%) | 5-11 |

| Hydroxypropyl cov ntsiab lus /% | 14-24 |

Cov chaw thov

? Cement-based thiab gypsum-based

? mortars

? Khoom noj khoom haus

? Tshuaj pleev ib ce

? Textiles

? Xim

? Ink

? Ntawv

? Ntoo

? Lwm yam kev siv cuam tshuam

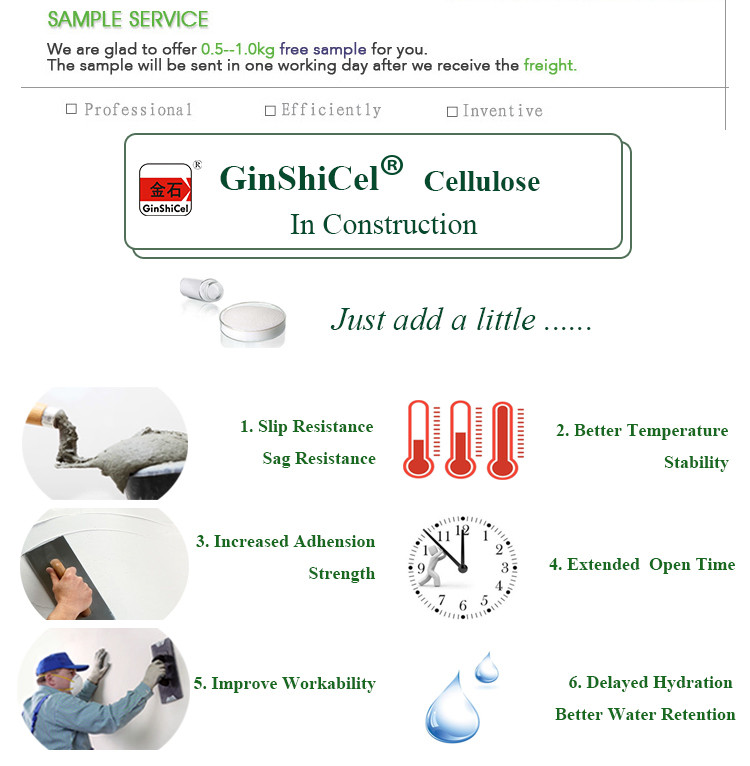

Kev ua haujlwm zoo

? Anti-sagging

? Ua kom lubricity ntxiv thiab ua kom daim ntawv thov smoother

? Ceev ceev

? Tiv thaiv txheej txheej thiab sib cais ntawm mortar; nce daim ntawv cog lus lub zog ntawm mortar

? Ncua sij hawm qhib ntawm mortar

cov duab ntxaws