Boemo bo phahameng ba HPS Starch Ether

Tlhaloso ea lihlahisoa

Starch ether ke sehlopha sa lihlahisoa tse fumanoang ka ho fetola lik'hemik'hale lihlopha tsa ether ho limolek'hule tsa starch, 'me hangata ke phofo e t?oeu kapa e t?oeu.

lit?obotsi tsa sehlahisoa

Thickening: e ka eketsa haholo viscosity ea sistimi, ea ntlafatsa ts'ebetso ea phallo.

Ho boloka metsi: ho boloka metsi ka katleho le ho fokotsa tahlehelo ea metsi.

Anti-slip: E ka thibela ho thella ha thepa ea thepa ea mohaho.

Ho lumellana hantle: Ho lumellana hantle le lisebelisoa tse fapaneng tsa moaho le li-additives.

t?ebeliso ea lihlahisoa

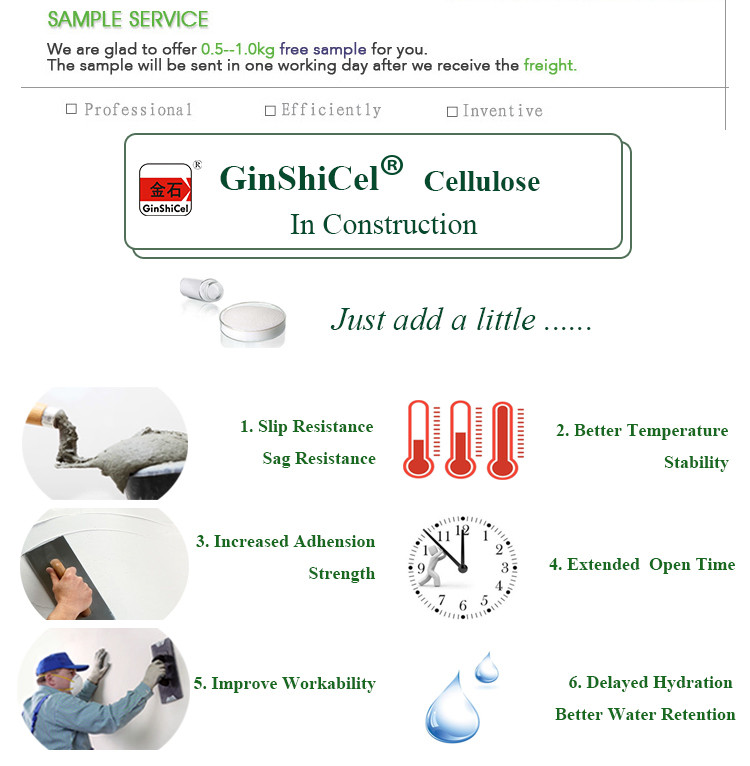

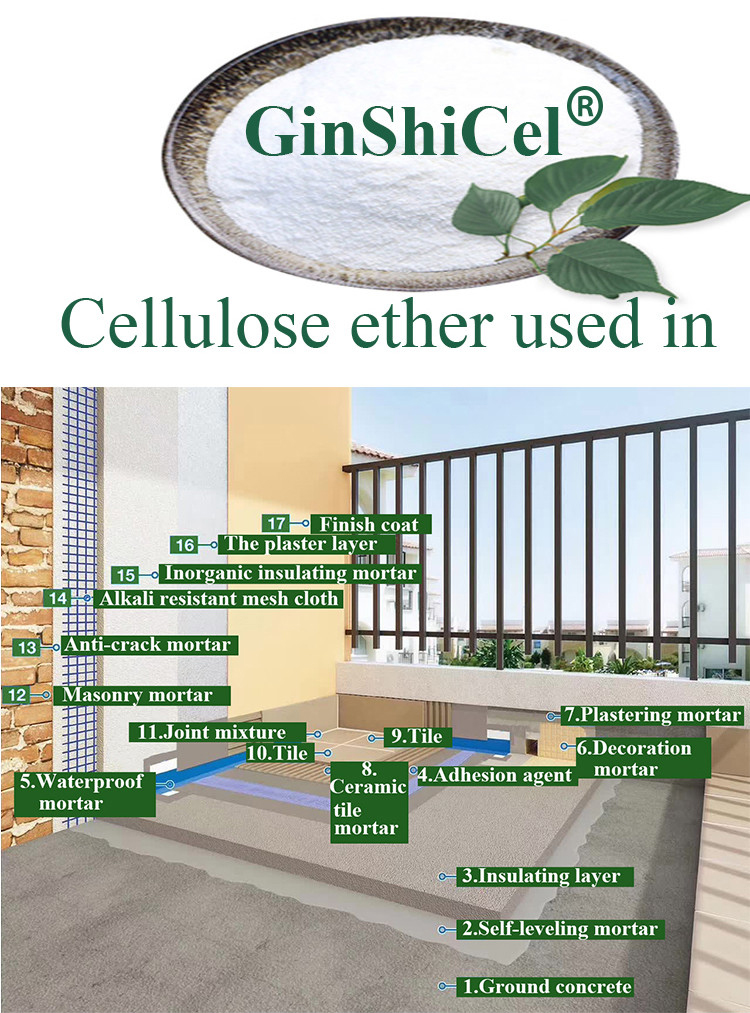

Sebaka sa meralo

Mefuta eohle ea seretse sa motsoako o omileng: joalo ka sekhomaretsi sa lithaele, seretse sa plastering, seretse sa ho kenya mocheso, joalo-joalo, se ntlafatsa ts'ebetso ea kaho le boleng ba sehlahisoa.

Putty: E ntlafatsa ho phunya ha batch le ho hanyetsa ha putty.

Indasteri ea Ceramic: E sebelisoa bakeng sa peista ea ceramic ho ntlafatsa mokelikeli oa eona le botsitso.

Indasteri ea ho roala: Eketsa viscosity le botsitso ba liphahlo, thibela ho fanyeha ha phallo.

Mokhoa oa tlhahiso

Ka kakaretso e lokiselitsoe ke karabelo ea starch le etherifying agent tlas'a maemo a itseng.

Litebello tsa 'maraka

Ka tlhokahalo e ntseng e eketseha ea lisebelisoa tse sebetsang hantle indastering ea kaho, hammoho le ntlafatso ea ts'ireletso ea tikoloho le litlhoko tsa ho boloka matla, ho sebelisoa ha starch ether ho thepa ea mohaho ho ntse ho eketseha, 'me tebello ea' maraka e pharaletseng haholo.

sebelisa litemoso

Polokelo e lokela ho bolokoa e omme le ho kenya moea ho qoba ho kopana ha mongobo.

Ha o sebelisoa, chelete ea tlatsetso e lokela ho laoloa ho latela maemo a ts'ebeliso le litlhoko tsa foromo.

Mefuta e fapaneng ea li-starch ethers e ka ba le phapang ea ts'ebetso 'me e lokela ho khethoa ho latela litlhoko tsa sebele.

Ka mohlala, ha ho sebelisoa sekhomaretsi sa tile ea ceramic, tlatsetso e loketseng ea starch ether e ka ntlafatsa viscosity ea pele le thepa e khahlanong le ho thella ea sekhomaretsi sa tile ea ceramic ho etsa bonnete ba hore tile ea ceramic e khomaretsoe ka thata; Ka putty, e ka ntlafatsa ho aha le ho hanyetsa ho phatloha ha putty.

Ka bokhut?oanyane, starch ether, e le motsoako o babatsehang, e phetha karolo ea bohlokoa liindastering tse ngata 'me e fana ka tharollo e sebetsang bakeng sa ho ntlafatsa boleng ba sehlahisoa le tshebetso.

Lipont?o tsa tekheniki

| Mohlala | HPS-301 |

|---|---|

| Ponahalo | Phofo e phallang e t?oeu kapa e bobebe |

| Fineness (80 mesh pass rate) | ≥98 |

| Boima ba bongata /g/L | ≥500 |

| Mongobo /% | ≤12.0 |

| PH(20%) | 5-11 |

| Likahare tsa Hydroxypropyl /% | 14-24 |

Libaka tsa kopo

? E thehiloeng ho samente le gypsum-based

? Liretse

? Lijo

? Litlolo

? Masela

? Penta

? Enke

? Pampiri

? Patsi

? Lisebelisoa tse ling tse amanang le tsona

Ts'ebetso ea kopo

? Anti-sagging

? E eketsa lubricity le ho netefatsa ts'ebeliso e bonolo

? Ho Thibela ka potlako

? E thibela ho beha le ho arola seretse; e eketsa matla a seretse

? E lelefatsa nako ea ho bula seretse

lintlha lit?oant?o