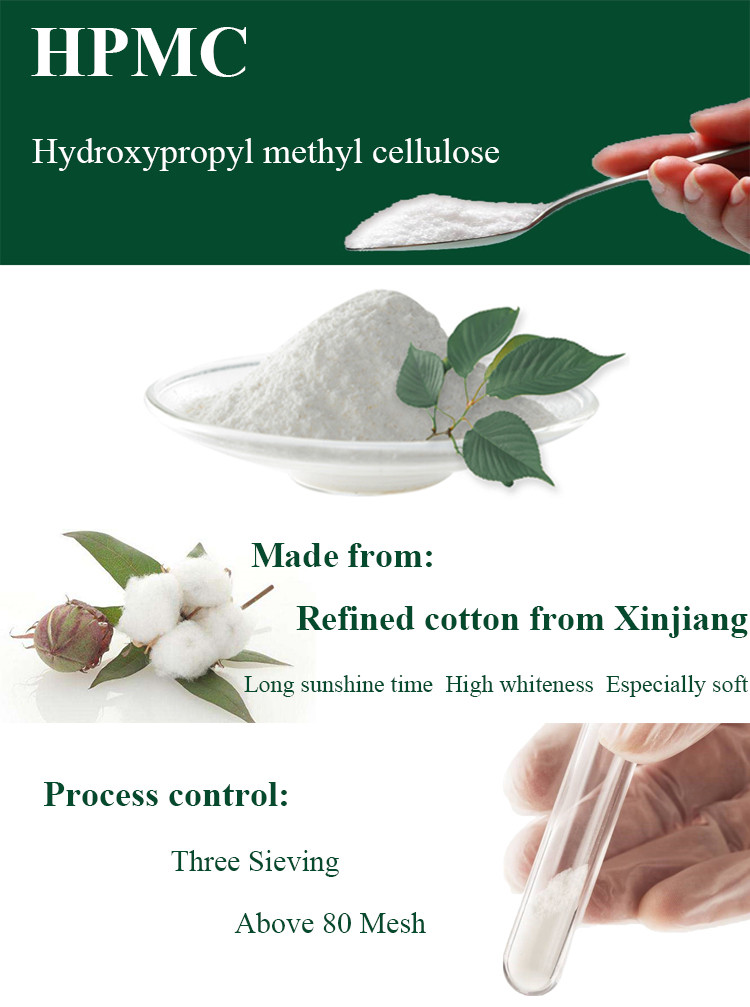

Ikhwalithi ephezulu ye-DF Defoamer White, impushana egeleza kalula

Uhlolojikelele lomkhiqizo

I-Defoamer (i-Defoamer) iyisengezo samakhemikhali esikwazi ukuqeda noma ukuvimbela ukukhiqizwa kwegwebu oketshezini.

izici zomkhiqizo

Ikhono lokukhipha amagwebu ngokushesha: lingabhubhisa ngokushesha ukuzinza kwegwebu, ukuze igwebu liqhume ngokushesha.

Umphumela wokucindezelwa kwegwebu ohlala isikhathi eside: Ngemva kokuba igwebu selisusiwe, ukukhiqizwa kwegwebu elisha kungavinjelwa isikhathi eside.

Ukuhambisana okuhle: Inokuhambisana okuhle nesistimu yokukhipha amagwebu futhi ayithinti ukusebenza okuyisisekelo kwesistimu.

Ukuzinza okuphezulu: Ukusebenza kokukhipha amagwebu okuzinzile ngaphansi kwezinga lokushisa elihlukile, i-pH nezimo zengcindezi.

Ubuthi obuphansi, ukuvikelwa kwemvelo: ukulimala okuncane emzimbeni womuntu kanye nemvelo.

ukusetshenziswa komkhiqizo

Ukukhiqizwa kwezimboni

Imboni yephepha: Susa igwebu ku-pulp, uthuthukise ikhwalithi yephepha.

Ama-coatings nopende: Vimbela ukwakheka kwegwebu ngesikhathi sokuxuba nokwakha.

Ukuphrinta kwendwangu kanye nokudaya: Xazulula inkinga yegwebu kunqubo yokudaya nokuqeda.

I-Petrochemical: Ekucwengisweni, ukukhiqizwa kwamakhemikhali ukuze kuqedwe igwebu, ukuqinisekisa inqubekelaphambili eshelelayo yokukhiqiza.

Ukucubungula ukudla

Inqubo yokuvutshelwa: Lawula igwebu oketshezini lokuvutshelwa ukuze uthuthukise ukusebenza kahle kokukhiqiza.

Ukucubungula ukudla: njengemikhiqizo kabhontshisi wesoya, iziphuzo nokunye ukukhiqizwa kokukhipha amagwebu.

Ukwelashwa kwamanzi

Ukwelashwa kwendle: vimbela ukukhiqizwa kwegwebu, thuthukisa umphumela wokwelapha.

Inqubo yokukhiqiza

Kunezinhlobo eziningi ze-defoamer nezinqubo ezihlukene zokukhiqiza. I-polyether type defoamer evamile ilungiswa ngokusabela kwe-polymerization, futhi i-silicone defoamer yenziwa nge-emulsification kawoyela we-silicone.

Amathemba emakethe

Ngokunwetshwa kwesikali sokukhiqiza ezimbonini ezahlukahlukene kanye nokuthuthukiswa kwezidingo zekhwalithi yomkhiqizo, isidingo semakethe se-defoamer siyakhula. Ngaso leso sikhathi, ukuthuthukiswa kanye nokusetshenziswa kwe-defoamer evumelana nemvelo futhi ephumelelayo nakho sekuphenduke inkambiso yokuthuthukiswa kwemakethe.

sebenzisa izinyathelo zokuphepha

Khetha uhlobo olufanele lwe-defoamer: Khetha ngokuya ngohlelo oluthile lohlelo kanye nembangela yegwebu.

Lawula inani lokwengeza: ukwengeza okuncane kakhulu kungase kungaphumeleli umphumela we-antifoam, okuningi kungase kuthinte ukusebenza kwesistimu.

Indlela yokwengeza elungile: Imvamisa ingengezwa ngqo noma ngemuva kokuhlanjululwa, ukuze kuqinisekiswe ukuhlakazeka okufanayo.

Isibonelo, ekukhiqizeni upende, ukukhetha i-defoamer efanelekile nokuyengeza esiteji esifanele kungaqeda ngempumelelo ama-bubbles futhi wenze ubuso bepende bushelelezi futhi bube flat; Ekwelashweni kwendle, ukungezwa okufanele kwe-defoamer kungathuthukisa ukusebenza kahle kokwelashwa futhi kunciphise umthelela wegwebu emvelweni.

Ngamafuphi, i-Defoamer idlala indima ebalulekile ezinkambisweni eziningi zokukhiqiza nezimboni, enikeza isiqinisekiso esiqinile sokuthuthukisa ukusebenza kahle kokukhiqiza kanye nekhwalithi yomkhiqizo.

Izinkomba zobuchwepheshe

| Imodeli | DF-6050 | |

|---|---|---|

| Ukubukeka | Impushana emhlophe, egeleza kalula | |

| PH(20%) | 5.0-9.0 | |

| Ukuminyana kwenqwaba /g/L | 200-400 | |

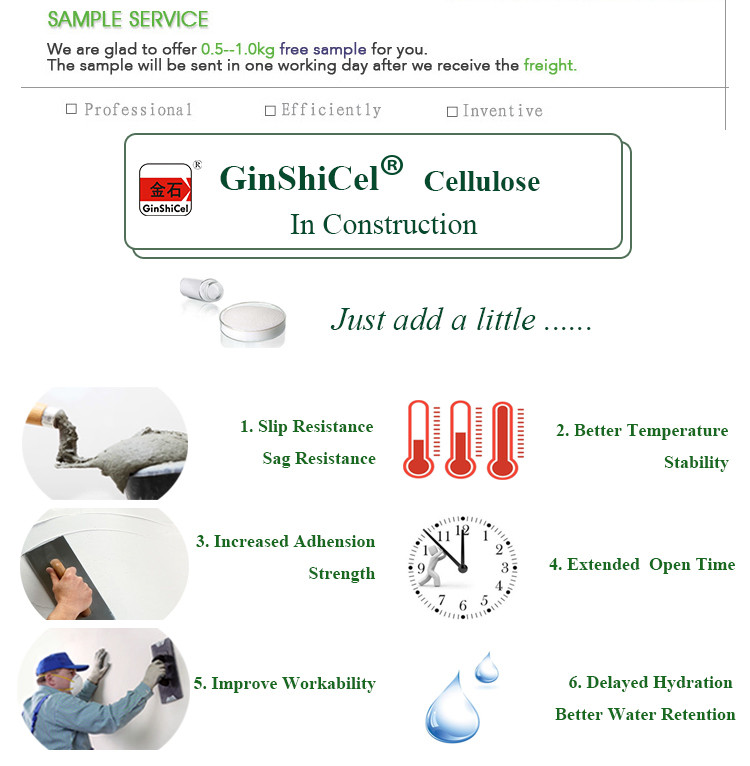

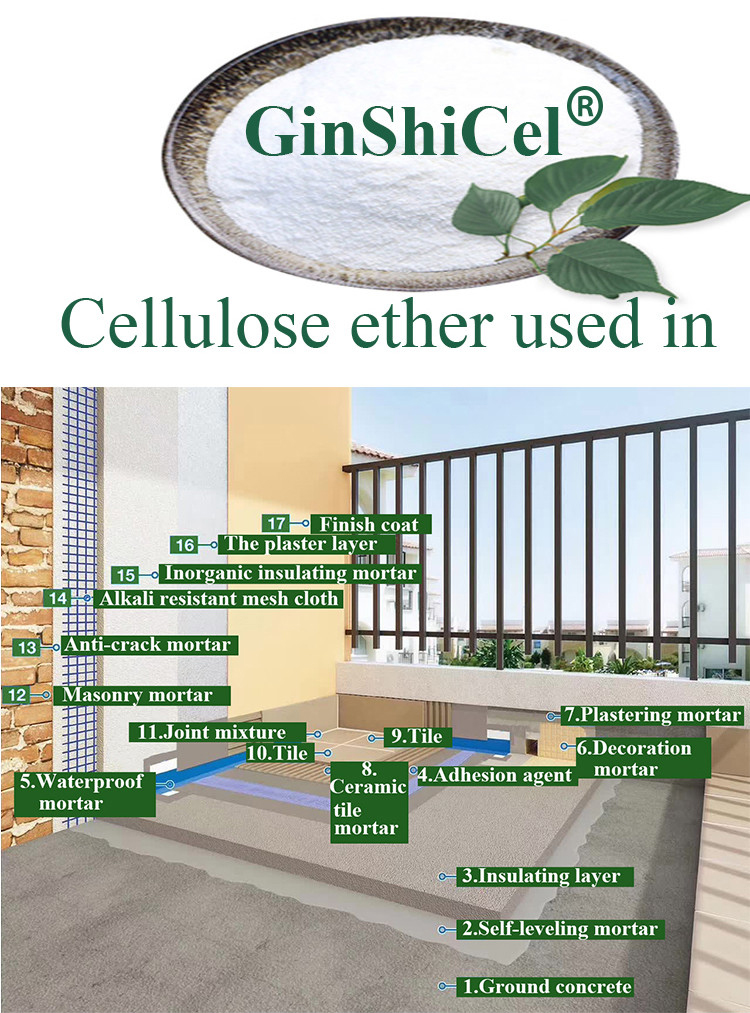

Izindawo zokufaka izicelo

? Lungisa udaka

? Impahla yokuqoqa

? I-GRC

? Ukufakwa phansi kwamatshe aphansi

Ukusebenza kohlelo lokusebenza

? Isivinini esikhipha amagwebu ngokushesha nokuzinza okuhle

? Ukucindezelwa kwegwebu

? Ukuzivumelanisa nezimo ezintweni ezihlukahlukene

? Ukusebenza kokumelana nokushisa okuphezulu

? Khulisa amandla kakhonkolo nezinye izinto

imininingwane izithombe